Weekly Progress Update

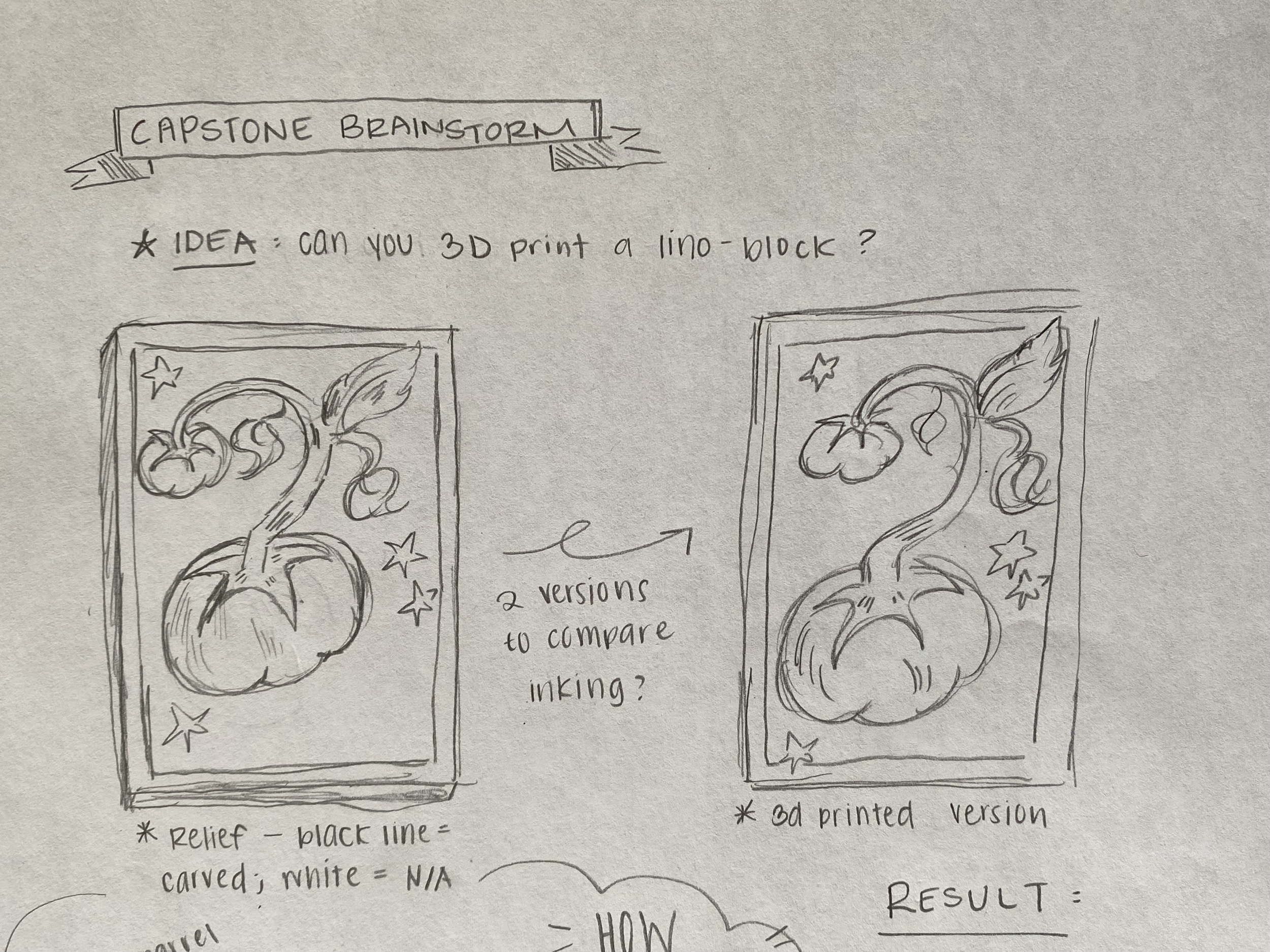

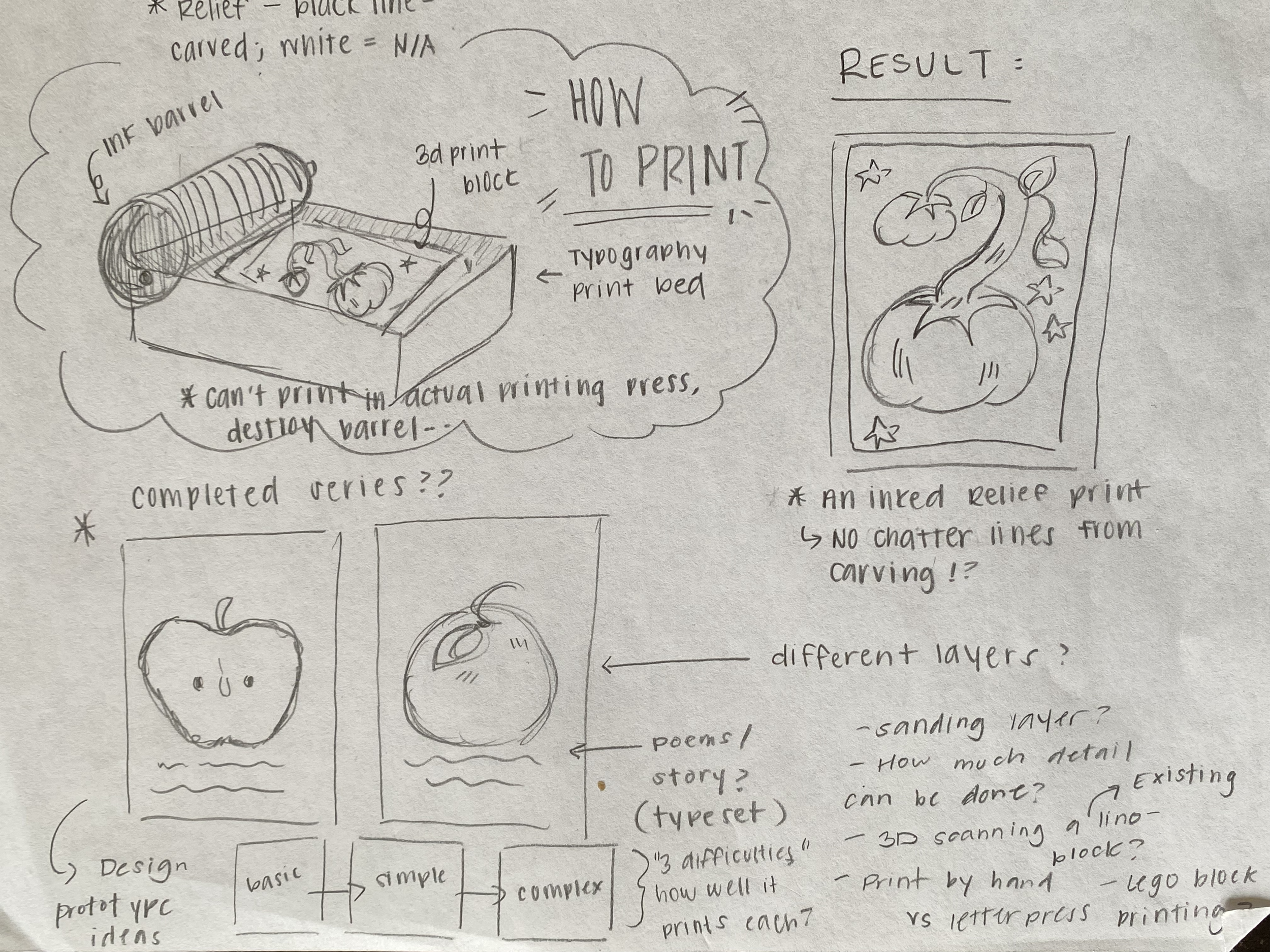

Over the weekend, I drew a rough project sketch of my idea and the questions I hope to answer. My capstone project will be combining relief printmaking and 3D printing, transforming both traditional and digital practices. As a result, these prints will come together as a series, with a typeset story/poem to connect them. I decided to treat this project mainly as an experiment; however, the end goal will be my results and the series of works I completed. Throughout the second week, we were tasked with developing our project and fleshing out the details. This was mainly done by completing an exhibition proposal or prospectus (which can be found here on my website, if interested).

I found it challenging to write a prospectus for my project. 1) I’ll admit, I was a bit hesitant about my project idea overall, and 2) I wasn’t entirely sure what I would need for the project or the process that would be going into it. Which led to a very short prospectus altogether. My project is literally titled “Untitled.” That’s how unsure I was, but by the fourth class, I felt better about my idea. As I discussed it with my peers (who are very knowledgeable about 3D printing), did research, and talked it over with my professor, Rafael Fajardo, the more I got into the groove of things.

For starters, I found a Reddit post on r/Linocuts posted by a user with the name @JustJazOnReddit about a year ago asking: “Hey linocutters I’m wondering if any of you have ever experimented with 3D printing designs instead of carving them into Lino. If so what happened?” Several comments mentioned mixed reviews, saying it failed due to an uneven surface with TPU or that the surfaces never hold the ink well due to separation and blotchy results. However, someone in the thread mentioned the artist Pete Prodoehl, who has been a publisher for RasterWeb since 1997.

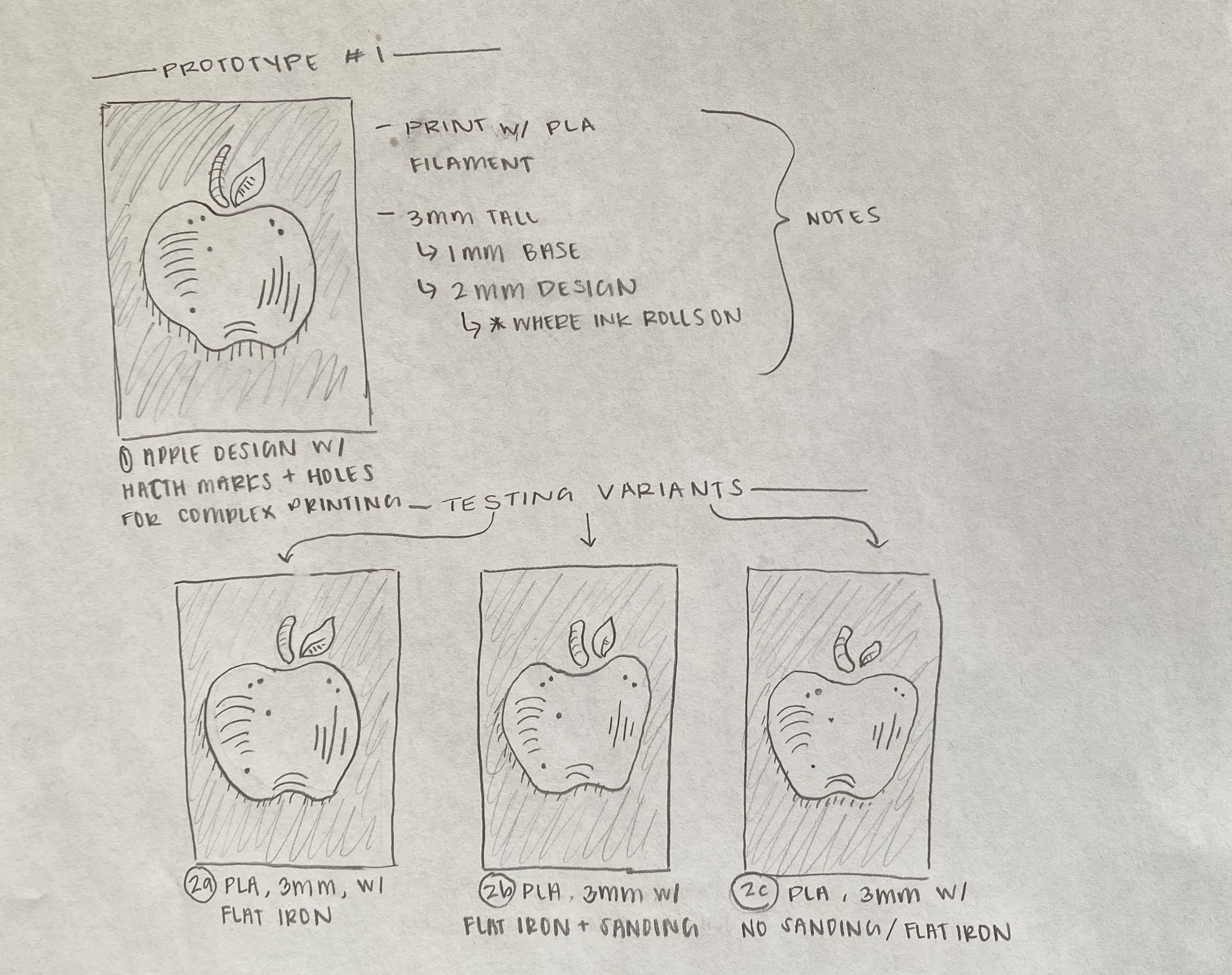

Prodoehl posted on 01/28/2024 his experiments with 3D-printed plates and the process. Some notable takeaways that I’ll be incorporating into my experiment are his measurements, the ironing feature on 3D software, and sanding down the plates. The plates are 3mm tall: 1mm for the base and 2mm for the design (where the ink rolls on during printing). I’m going to use this as a base for now and adjust after I test print the plates next week on the letterpress and with a baren. As for the extra steps he took with ironing and sanding, I’m going to test them as separate variables. Over this weekend, I’m going to test-print 3 plates with the same design and filament, varying factors. Prodoehl also mentioned using water-based printmaking inks for easy cleanup, but I’m going to try both water-based and oil-based inks and see which I prefer. Personally, I would go with oil-based, since it’s a common practice for me. Plus, the last time I used water-based ink, I noticed how quickly it dried on the surface I was printing on. Which can prove to be a challenge if I want to print a lot of editions AND if I just so happen to need to step away from my printing station for a bit. But that’s what this experiment is for!

I’ve also had to figure out other aspects yesterday. Like the 3D printer I’m using, the type of filament, and the paper. The status of the 3D printer in EDP is pending at the moment, but I have my boyfriend’s 3D printer and the university’s Innovations Lab 3D printer, if needed. Which is super helpful! As for the filament, Prodoehl used PLA, but Rafael had shown me a student print with a squishy texture, most likely made with TPU. For now, I’m going to experiment with PLA since that’s what I have readily available! Lastly, paper. I was offered the paper used in a previous Typography class I was in, which I’m considering. However, I also thought about making my own paper. The only difference would be needing to buy bigger frames for the paper, so I can fit both my design and text comfortably on the page. However, this is less a skill I learned in EDP and more an ongoing learning experience since the summer of 2024. But it would be cool if that were an option; it is not necessary for my capstone!

The goal for this weekend is to start 3D printing plates and get them prepped for ink-based printing, which I’m looking forward to!